Everything about Mhs - Material Handling Supply Inc.

Table of ContentsLittle Known Facts About Mhs - Material Handling Supply Inc..An Unbiased View of Mhs - Material Handling Supply Inc.The Best Guide To Mhs - Material Handling Supply Inc.Examine This Report on Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

You will certainly require to seriously consider your earnings prior to you purchase. It's unwise to invest in this equipment if you can't scale your organization to the factor that this investment is rewarding. Once your automated system is in place, you won't have much flexibility in your floor room. Additionally, you require to consider your lasting organization goals.

Like any equipment, computerized tools can malfunction and also break. Maintenance prices are another disadvantage of automated material managing systems.

The only means to avoid this is to set up normal maintenance on all components of the system. It's unlikely someone in your stockroom knows just how to do the task, so you'll have to hire a professional or expert, which is expensive.

Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

One of the most current innovations in product taking care of systems help to meet the demands of numerous companies that need dealing with equipment. With the complex material managing procedures, having a useful product taking care of system that adjusts to the specific needs of operators and commercial companies is a true advantage. The adhering to are some of the benefits of making use of material carts and trains to move containers or system lots from the stockroom to the building and construction site: Saves moneyImprove securityLessen downtimeEnhance ergonomicsImprove efficiencyDecrease website traffic on forkliftsExpand capacitySave spacePromote adaptabilityImprove the job environmentMaterial managing carts and trains are the best choices today, whether you are an assembler, production engineer, logistic operator, logistics designer, upkeep engineer, security engineer, or administration head.

The continual transition to Market 4.0 and a smarter functioning or making environment is also dependent on proper product administration. Utilizing semi-automatic or entirely automated solutions is the means to go right here. The benefits of this product dealing with technology consist of decreased downtime and faster just-in-time distribution and manufacturing.

Cranes and hoists are essential components in many sectors, playing a pivotal function in product handling and lifting operations. Guaranteeing the dependable and secure procedure of these makers is vital. Routine upkeep of cranes and hoists provides a multitude of benefits that directly affect security, performance, and the bottom line of services that count on them.

Indicators on Mhs - Material Handling Supply Inc. You Should Know

Similar to any other equipment, cranes and hoists have a limited life-span which is affected by the kind of usage. Additionally, normal maintenance can considerably assist expand this life-span. Through lubrication, components substitute, and preventative measures, the deterioration on essential components is lessened. Therefore, these devices can continue to be in procedure for several years, giving an outstanding return on financial investment.

This implies smoother and more accurate activities, which is essential in applications requiring precision, such as manufacturing and construction. Effectively kept devices additionally experiences fewer failures, reducing expensive downtime. Cranes and hoists deal with heavy tons and run in environments where security is of utmost importance as any kind of messing up of the tons can create loss of human lives along with possessions under procedure.

Little Known Questions About Mhs - Material Handling Supply Inc..

Failing to abide by these rules might lead to fines, lawful concerns, and reputational injury. Routine maintenance makes sure that your devices satisfies these requirements, helping you stay certified with sector requirements and regulations. Downtime is the adversary of productivity. Unforeseen break downs or failures in crane and hoist systems can bring procedures to a grinding halt.

Properly maintained cranes and hoists have a tendency to be extra environmentally friendly. Routinely preserving your product managing equipment can contribute to a greener and more lasting future.

Expanding the solution life of your crane and hoist equipment is not just a prudent economic choice but likewise essential for maintaining safety and functional performance. Below are numerous methods to make the most of the longevity of your crane and hoist systems: Invest in detailed training for crane and hoist operators. Well-trained operators are much less most likely to abuse tools, leading to minimized wear and tear.

Some Known Questions About Mhs - Material Handling Supply Inc..

It is crucial throughout normal crane and hoist operations. As an example, when an operator is moving a tons, especially in situations where the designated area might be occupied by one more crane or production line workers, the danger of accidents increases substantially. Therefore, clear and continual interaction is vital to make certain risk-free and efficient operations.

Overwhelming a crane or hoist can speed up wear find out here now and potentially trigger devastating failures. Enlighten your crane drivers on the relevance of abiding by load limitations and offer clear lots ranking info for all devices (https://www.callupcontact.com/b/businessprofile/MHS_Material_Handling_Supply_Inc/9235051). Adhering To OEM (Original Tools Manufacturer) standards vigilantly is crucial, particularly thinking about that various crane and hoist designs may have special demands demanding specialized interest

These aspects collectively contribute to expanding the equipment's life expectancy, minimizing downtime, and protecting against unforeseen break downs. Makers suggest the usage of real spare parts and products for upkeep, maintaining the devices's initial quality and efficiency.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Shaun Weiss Then & Now!

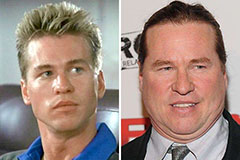

Shaun Weiss Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Lucy Lawless Then & Now!

Lucy Lawless Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!